Tire News & Information

Free shipping

Best price guarantee

SimpleCrew exclusive savings

0% financing options

Tire replacement coverage

24/7 roadside assistance

Easy returns

Solid tires are a unique alternative to traditional pneumatic tires, offering a durable and resilient solution for various industrial applications. These tires are constructed entirely from solid rubber or other sturdy materials, eliminating the need for an air-filled cavity.

Solid tires are designed to withstand the toughest working conditions, providing superior puncture resistance and extended service life compared to their pneumatic counterparts. They are commonly found on forklifts, skid steer loaders, and other heavy-duty equipment in industries such as construction, mining, and material handling.

Understanding the construction, benefits, and applications of solid tires is essential for businesses and individuals looking to optimize their equipment's performance and minimize downtime. In this article, we will explore the world of solid tires, providing valuable insights to help you make informed decisions when selecting tires for your specific needs.

What are solid tires?

Solid tires are a type of tire that is constructed entirely from solid rubber or other resilient materials, without any air-filled cavity. Unlike pneumatic tires that rely on compressed air for load support and cushioning, solid tires depend on their thick, dense rubber construction to bear the weight of the vehicle and absorb shocks.

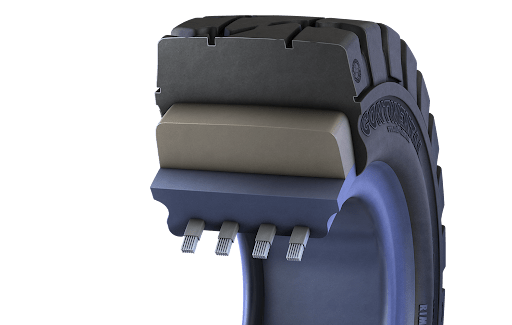

The design of solid tires consists of a solid rubber tread and sidewall that is either bonded to a metal band or pressed onto a metal wheel. This construction eliminates the risk of punctures and air leaks, making solid tires an ideal choice for rough terrain and hazardous environments where a flat tire could lead to costly downtime or even catastrophic failures.

Solid tires provide a maintenance-free solution for many industrial applications, as they do not require air pressure monitoring or refills. They are built to withstand the harshest conditions, offering superior resistance to cuts, chunks, and impacts compared to pneumatic tires.

Solid Tire Construction

Creating solid tires involves a detailed process to achieve the desired durability and performance. Initially, manufacturers select rubber compounds known for their toughness and ability to withstand extreme conditions. These compounds ensure the tire can handle both rough surfaces and heavy loads.

Manufacturing Methods

- Metal Core Construction: Some solid tires are built around a metal core. Rubber layers are added onto this core, gradually forming the tire's body.

- Adaptable Rim Design: Other solid tires are crafted to fit standard rims, allowing them to be easily swapped with pneumatic tires when needed.

Shaping and Finishing

Once the rubber layers are adequately thick, hydraulic presses shape the tire to precise specifications. The tire then enters a mold, where heat treatment occurs—vulcanization. This step finalizes the tire’s dimensions and tread design, ensuring it is ready for the rigorous demands of industrial environments.

These processes guarantee that solid tires provide outstanding reliability and durability for a variety of equipment used in demanding conditions.

Benefits of Solid Tires

Solid tires excel in reliability and durability, making them a top choice for demanding environments. Crafted from resilient materials, they handle sharp objects and rough terrains with ease, ensuring continuous operation without the interruptions common to pneumatic tires. This robust design minimizes maintenance needs, helping businesses avoid frequent repairs and associated costs.

Longevity and Stability

A key advantage of solid tires is their impressive lifespan. These tires endure significantly longer than pneumatic options, translating to fewer replacements and reduced expenses over time. Their sturdy design provides excellent support under heavy loads, ensuring consistent performance and safety in various operations.

Low Maintenance and Versatility

Requiring minimal upkeep, solid tires eliminate the need for air pressure checks and related maintenance tasks. This simplicity makes them appealing for operations needing efficiency and reduced manpower. Furthermore, solid tires adapt well to diverse environments, from construction sites to industrial settings with harsh conditions, proving their versatility and reliability in heavy-duty applications.

Applications for Solid Tires

Solid tires play a crucial role across multiple industries, offering resilience and adaptability in challenging work environments. These tires are essential for equipment that must endure continuous use on tough surfaces without frequent damage.

Industrial and Material Handling

In material handling, solid tires are indispensable for forklifts and similar machinery. Designed for indoor settings, they perform exceptionally well on hard, smooth surfaces. Their solid construction eliminates the risk of flats, allowing forklifts to handle heavy loads efficiently and maintain productivity in busy warehouses and distribution centers.

Construction and Demolition

The construction industry benefits greatly from solid tires, especially for skid steer loaders and compact construction equipment. These tires excel in demolition sites, recycling centers, and scrap yards, where sharp debris and uneven terrain are common. Their robust nature ensures they can navigate these harsh environments with minimal downtime and reduced maintenance expenses.

Heavy-Duty and Specialized Equipment

Solid tires are vital for heavy-duty applications like mining and port operations. Equipment such as wheel loaders and excavators rely on the stability and impact resistance provided by solid tires. This is crucial in environments that demand high load capacities and exposure to severe conditions. Moreover, in ports and rail yards, vehicles like straddle carriers and terminal tractors benefit from the durability and stability that solid tires offer, ensuring safe handling of heavy loads.

The versatility of solid tires extends to ground support at airports, where they are used on aircraft tow tractors and baggage/cargo tractors. These applications require dependable performance and puncture resistance to keep operations running smoothly and without interruptions.

Choosing the Right Solid Tire for Your Needs

Selecting a solid tire requires careful consideration of various factors to ensure it meets the demands of your equipment and operating environment. The right tire choice influences not only performance but also safety and longevity, making it crucial to assess aspects such as load capacity, tread configuration, and material properties.

Equipment Load and Tire Specifications

It's essential to match the tire's load capacity to the demands of your machinery. Assess the weight your equipment handles regularly to ensure the tire can support it effectively. Consider the tire's dimensions and ply rating to confirm compatibility with your equipment's specifications, which will enhance stability and prevent overloading.

Tailored Tread Patterns for Terrain

Terrain plays a pivotal role in determining the appropriate tread pattern. For operations on smooth, hard floors like those in factories or logistics hubs, tires with a plain tread ensure minimal rolling resistance. Conversely, for off-road or rugged terrain, such as construction or demolition sites, a tread with deep grooves and lugs provides better traction and control.

Durability and Material Quality

In environments where durability is paramount, opt for tires made from high-grade rubber compounds designed to resist cuts and chunks. These materials ensure the tire withstands the rigors of harsh conditions effectively. Consulting with experienced tire specialists or manufacturers can offer valuable guidance, helping you select the most suitable tire for your specific application and operational requirements.

At SimpleTire, we understand the importance of selecting the right solid tires for your unique needs. Our team of experts is dedicated to helping you find the perfect tires that deliver optimal performance, durability, and value. Shop for tires online with us today and experience the convenience of our user-friendly platform, extensive selection, and unbeatable deals.

Ready to find the perfect tires?

Search By